Do you know the working principle and applications of a glass cutter?

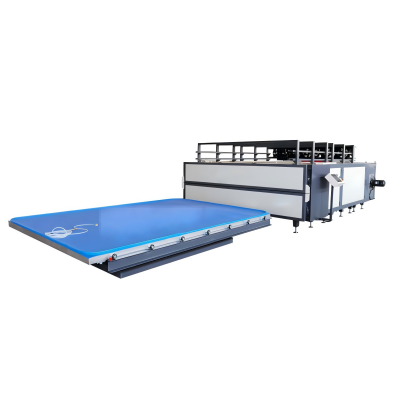

A glass cutting machine is the first “make-or-break” step in most flat-glass factories. When the cutting stage is stable, everything downstream—edging, washing, tempering, lamination—runs smoother. When it isn’t, scrap rises, edge defects appear, and operators spend the day chasing inconsistencies. This guide explains the glass cutting machine working principle in plain terms, shows where CNC scoring fits compared with waterjet and laser, and lists the practical configuration and maintenance points buyers should verify before purchasing a glass cutting machine line.

What a glass cutting machine actually does

In industrial production, a glass cutting machine does not “saw” through the sheet. Instead, it relies on the physics of glass scoring and breaking:

•Scoring (scribing): A diamond or carbide wheel creates a controlled surface flaw along a programmed path.

•Controlled separation: The line is then opened with bending force, localized pressure, or air-assisted breaking so the crack propagates through the thickness.

For procurement and engineering teams, a few terms matter:

•CNC glass cutting machine: Automates scoring paths with X–Y motion control for straight lines, arcs, and internal contours.

•Diamond wheel glass cutter: The scoring wheel (often sintered diamond or cemented carbide) shaped to generate a consistent score.

•Industrial glass cutting machine: A production-oriented system designed for repeatability, uptime, and integration with downstream conveyors.

Glass cutting machine working principle from loading to finished blanks

A modern glass cutting machine typically follows a repeatable workflow. While the details vary by automation level, the core logic stays the same.

1. Loading and positioning

Sheets are loaded by vacuum lifter or tilt-bar onto an air-float or vacuum table. Sensors (edge sensors or alignment lasers) reference the sheet to the machine coordinate system so the cut program matches the actual glass position.

2. CNC scoring

The cutting head moves along X–Y axes, and the controller coordinates the scoring parameters:

•Wheel pressure: Too high increases chipping risk; too low leads to incomplete separation.

•Travel speed: Must be optimized for the specific glass thickness.

•Path quality: Handling straight lines, arcs, and inner contours with precision.

In many standard architectural and automotive applications, a well-configured CNC glass cutting machine can target dimensional accuracy around ±0.2 mm, assuming correct setup, stable handling, and routine calibration.

3. Separation / breaking

After scoring, the glass cutting machine applies controlled force—break bars, localized pressure points, or air jets from below—to open the score line. The goal is a clean break that minimizes chips and protects edge strength for downstream processing.

4. Transfer to downstream processes

Finished blanks move to edge grinding/polishing, washing, tempering, or lamination. In a well-planned layout, the glass cutting machine becomes the “traffic controller” that keeps the entire line fed without bottlenecks.

CNC vs waterjet vs laser vs manual methods

Different technologies exist, but they serve different production realities. For most plants, the glass cutting machine based on CNC scoring remains the throughput leader.

MethodBest Fit (Geometry & Thickness)Edge & Thermal ImpactSpeed & Operating CostTypical Use

CNC scoring glass cutting machineCommon flat glass (often 2–19 mm), high-volume shapesGood; usually followed by light seaming/edgingVery fast; low consumablesArchitectural, automotive, furniture

Waterjet glass cutting (abrasive)Thick, laminated, or complex contoursExcellent; no heat-affected zoneSlower; higher consumablesSpecial shapes, small batches

Laser cuttingMainly thin or specialty glassFine, but HAZ risk depending on processHigher capex; medium speedElectronics, displays

Manual scoring & breakingLow volume, limited precisionOperator-dependentLow equipment cost; high laborSmall shops, rework

In practice, plants often keep a primary CNC glass cutting machine for daily production and use waterjet glass cutting or laser for “exception” parts where scoring cannot guarantee yield.

Key components that determine yield and edge quality

When comparing an industrial glass cutting machine, focus on the parts that influence consistency—not just the brochure speed.

•Cutting head and wheel system: Stable wheel mounting, easy wheel change, consistent pressure control.

•Motion system: Servo drives and precision linear guides that maintain repeatability across long shifts.

•Worktable: Air-float plus vacuum hold-down to prevent micro-movement during scoring.

•Control and software: Reliable CNC, nesting optimization, optional label/QR printing, production statistics, and remote diagnostics.

Before ordering, confirm your sizing and integration requirements:

•Maximum sheet size and daily output target

•Thickness range and glass types (clear, coated, laminated)

•Tolerance requirement and downstream edge specification

•Line integration (washer, IG line, tempering furnace)

•Available power, compressed air, and dust-management conditions

If you’re planning a complete line, you can review typical layouts on our product page: glass cutting line solutions.

Application-focused configuration notes

Architectural glass

A glass cutting machine for architectural work typically prioritizes large sheets, high nesting yield, and clean separation to reduce edging time. Common thickness ranges fall roughly within 3–19 mm depending on the project.

Automotive glass

Automotive production values repeatability and traceability. A CNC glass cutting machine paired with automatic labeling (including QR options) helps reduce mix-ups and supports tighter process control.

Furniture and mirrors

Furniture and mirror buyers often care most about cosmetic edge results after edging and polishing. For this segment, stable scoring, clean break behavior, and fast program changeovers improve both throughput and finish quality.

Electronics and optics

Plants handling thin or specialty glass may mix a smaller glass cutting machine for scoring with laser or waterjet for specific contours and materials.

Maintenance and troubleshooting that prevents scrap

A glass cutting machine is only “accurate” when it is clean, calibrated, and running with healthy consumables.

Daily checks

•Verify vacuum and air pressure stability

•Inspect the scoring wheel for wear or chipping

•Clean table surfaces to prevent scratches and slip

Weekly checks

•Calibrate with reference parts

•Inspect sensors, limit switches, and cable carriers

•Check belts/hoses for early wear

Monthly checks

•Inspect linear guides and bearings for play

•Review software logs and defect trends (chips, break wander, scratches)

Common defect mapping for a glass cutting machine:

DefectLikely CauseFast Fix

Edge chippingWorn wheel or incorrect pressureReplace wheel; reset pressure

Break line wandersScore too shallow/deep or wrong break forceTune scoring + breaking settings

Surface scratchesContamination on table/rollersClean supports; improve handling

FAQ for selecting an industrial glass cutting machine

What thickness can a CNC scoring system handle?

Most scoring-based glass cutting machine setups cover about 2–19 mm depending on model, glass type, and wheel configuration.

What accuracy is realistic?

With correct handling and regular calibration, many users target around ±0.2 mm for common architectural and automotive parts on a CNC glass cutting machine.

How quickly can a new line be installed?

Lead time depends on automation level and options. We typically support layout consultation, installation, commissioning, and operator training so your glass cutting machine reaches stable output faster.