Choosing a Full Automatic Butyl Extruder for Long-Term Production Efficiency

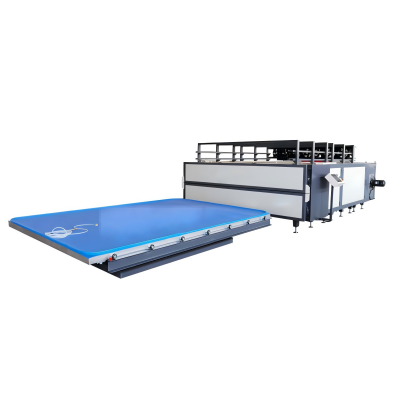

Equipment selection should always be based on long-term performance rather than short-term cost. This is especially true for primary sealing equipment. A Full Automatic Butyl Extruder offers advantages that extend well beyond automation.

An Automatic Butyl Extruder Machine ensures stable output by reducing human influence on the sealing process. This stability becomes more important as production volumes increase and delivery schedules tighten.

With an Automatic Butyl Coating Machine, sealant usage becomes more predictable. Precise extrusion reduces over-application, helping control material consumption and operating costs.

From a line-integration perspective, a Full Automatic Butyl Extruder works smoothly with spacer bending machines and insulating glass assembly lines. This compatibility simplifies production planning and future upgrades.

Factories that invest in automatic butyl extrusion are often better prepared for stricter quality standards and international market requirements. Instead of frequent adjustments, production becomes more process-driven and repeatable.

In the long run, choosing the right Automatic Butyl Extruder Machine is not about speed alone—it is about building a stable and scalable insulating glass production system.