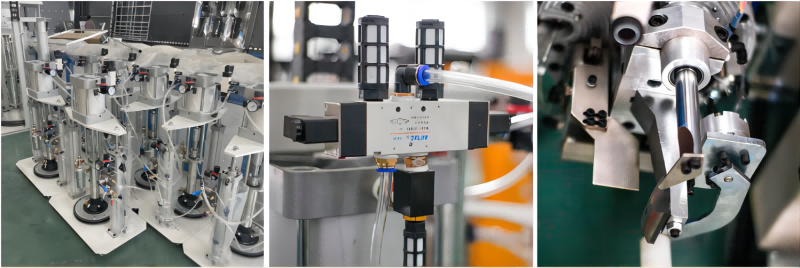

Two Pump Silicone Sealant Sealing Machine Extruder

1)It is produced with best technology in China and abroad Used for coating sealant for the second seal of insulating glass with aluminum spacer.

2)A(White) and B(Black) component sealant pump use Korean original pneumatic system, reversing sensitive and reliable

3)Unique convenient adjustable ratio, guarantee the accurate sealant ratio upon to highest requirements.

4)Anti-back flow control structure.

5)Mixed rate detector can control the rate of A and B group sealant

6) Sealant extruding is continuous and even with good sealing finish,high efficiency

Two Pump Silicone Sealant Sealing Machine Extruder.It has the following advantages and performance:

Two Pump Silicone Sealant Sealing Machine Extruder Its advantages and features:

The key parts are from America- the well known brand GROCO..The curative agent hydraulic pressure system have 2 sets of filtration devices that improved the mixing uniformity and solidification performanceort .The valves ports of the basic material pump, solidification pump and proportion pump all adopts the special alloy with zero leakage.the mixing system adops the international popular static reciprocating belt type mixer and imported mix mandrill .

Model |

Pakage and Delivery:

1.For big machine and full container load, usually wrapped in stretch film.

2.For open top container load, put on top grade plastic overcoat and tarpaulin to protect the equipment from moisture and water. 3.For less than container load, iron frame fixed and standard export wooden case for optional.