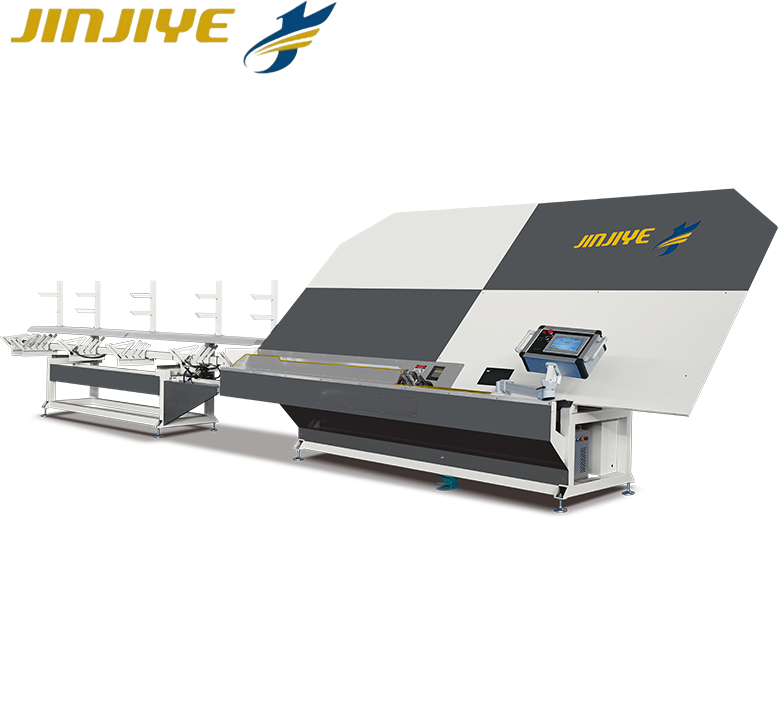

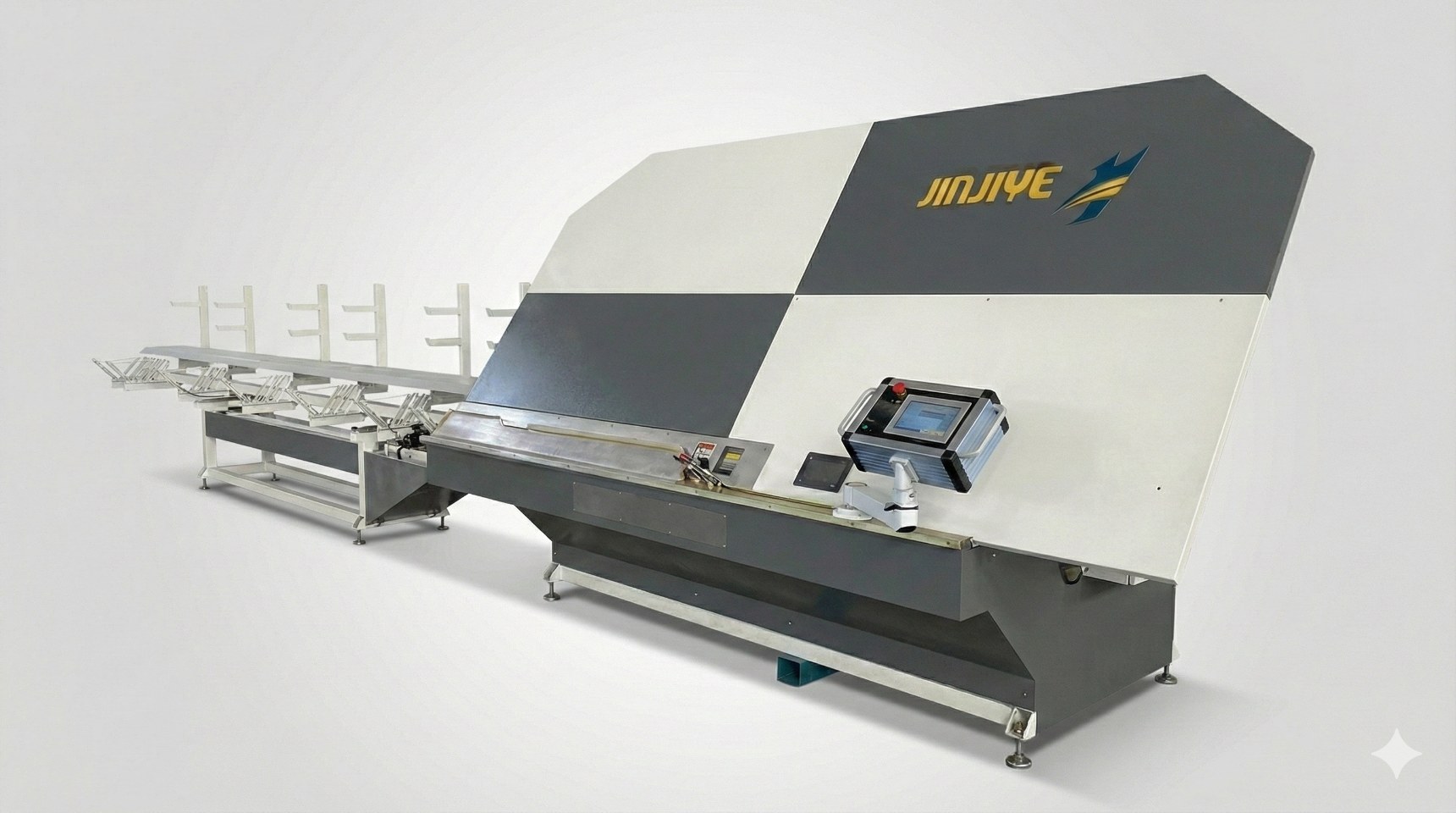

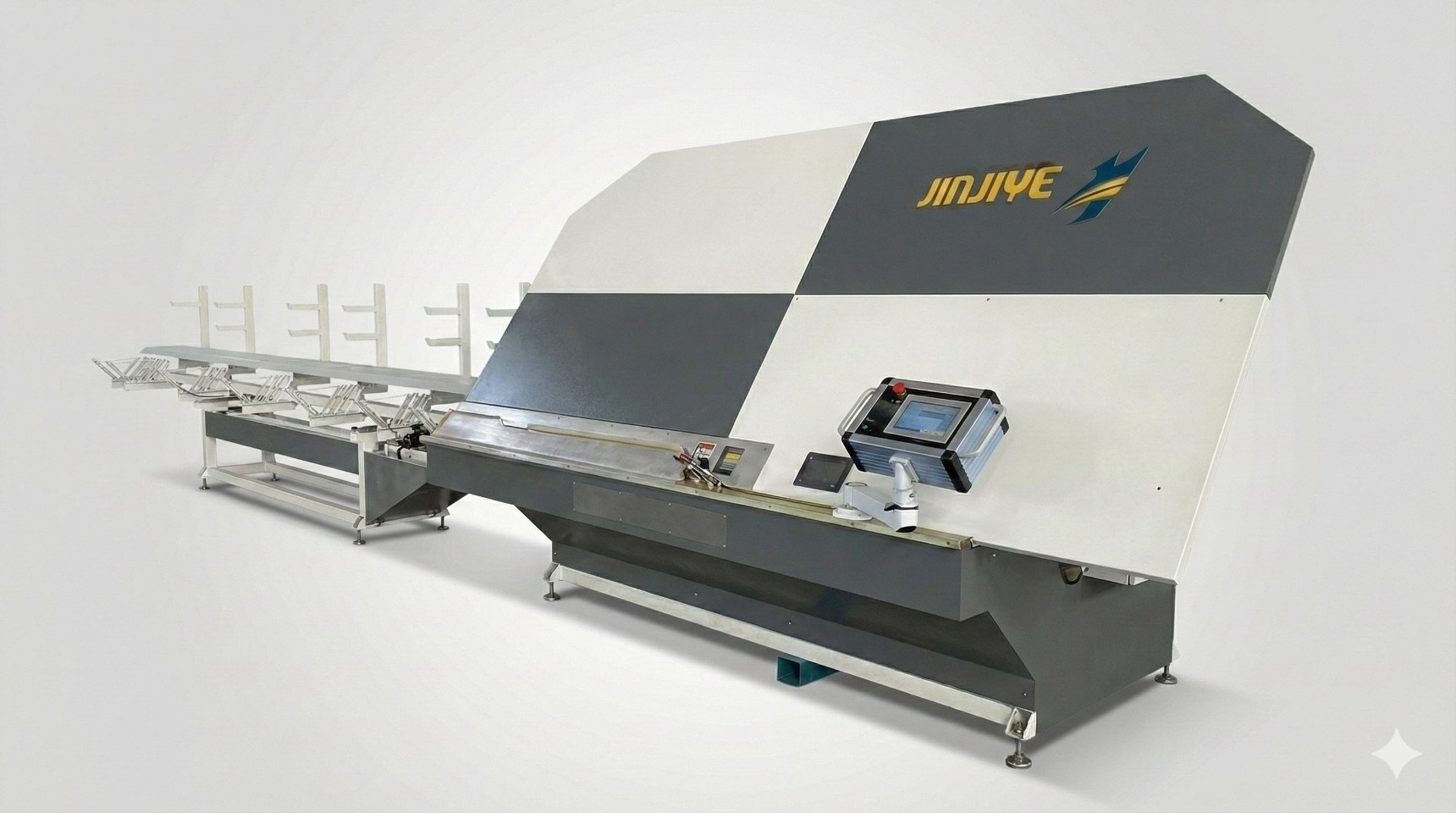

Aluminum Spacer Bending and Cutting Machine

• Integrated automatic feeding, bending, and cutting, boosting efficiency by 30%–50% and enabling 24/7 operation

• High-precision servo control with ±0.1° bending accuracy and ±0.05mm length tolerance

• Consistent quality reduces rework and ensures uniform aluminum bars

• Only 1–2 operators required, cutting labor costs by over 60%

• Flexible for multiple profiles; one-touch program switch completes changeovers in 10 minutes

• Real-time data monitoring and intelligent production management

• Durable structure with automatic lubrication, designed for 8–10 years of service life

The Automatic Aluminum Spacer Bending Machine is a core machine in the insulated glass production line, specially designed for bending aluminum spacers into precise and consistent spacer frames.

This machine integrates automatic feeding, aluminum spacer bending, cutting, and intelligent control, helping insulated glass manufacturers improve production efficiency, reduce labor costs, and ensure stable IG unit quality.

As a professional aluminum spacer bending machine manufacturer, we provide reliable solutions for modern insulated glass factories worldwide.

Automatic Aluminum Spacer Bending Machine Features

Automatic aluminum spacer feeding and positioning system

High-precision aluminum spacer bending with perfect 90° corners

Automatic cutting with smooth and clean spacer edges

Supports rectangular and special-shaped insulated glass spacer frames

Compatible with insulated glass production line equipment, including desiccant filling machines and butyl extruders

Model

JYJ-02 (semi-automatic)

JYJ-03 (automatic)

Power supply

220V 50Hz

220V 50Hz

Power

2.2KW

2.5KW

Supply gas pressure

0.5-0.8Mpa

0.5-0.8Mpa

Maximum bending size

2000*2000mm

2000*2000mm

Minimum bending size

250*250mm

250*200mm

Overall dimension

3800*1200*1900mm

10500*2200*2600mm

Weight

400kg

1500kg

Advantages of Aluminum Spacer Bending Machine

High Precision Bending

The automatic aluminum spacer bending machine adopts PLC and servo control, ensuring accurate spacer frame dimensions and minimal tolerance in insulated glass production.

High Efficiency for IG Production

Fully automatic operation allows continuous production, making it ideal for high-output insulated glass factories and large-scale IG unit manufacturing.

Stable and Durable Performance

Manufactured with high-quality mechanical structures and electrical components, the aluminum spacer bending machine guarantees long-term stable operation and low maintenance cost.

Easy Operation and Low Labor Cost

The touch screen control system makes operation simple and intuitive. One operator can handle the machine, significantly reducing labor input.

Applications

The automatic aluminum spacer bending machine for insulated glass is widely used in:

Insulated glass manufacturing plants

Architectural glass processing factories

Door and window system manufacturers

Companies upgrading to automatic insulated glass production lines

Optional Functions

Laser marking aluminum spacer bending machine for production traceability

Special-shaped insulated glass spacer frame bending

Quick spacer size change system

Integration with full automatic insulated glass production lines

Automatic Aluminum Spacer Bending Machine Manufacturer

As an experienced automatic aluminum spacer bending machine supplier, we focus on providing high-quality equipment for insulated glass production.

Our machines are designed to help customers improve efficiency, reduce production costs, and achieve stable insulated glass quality.