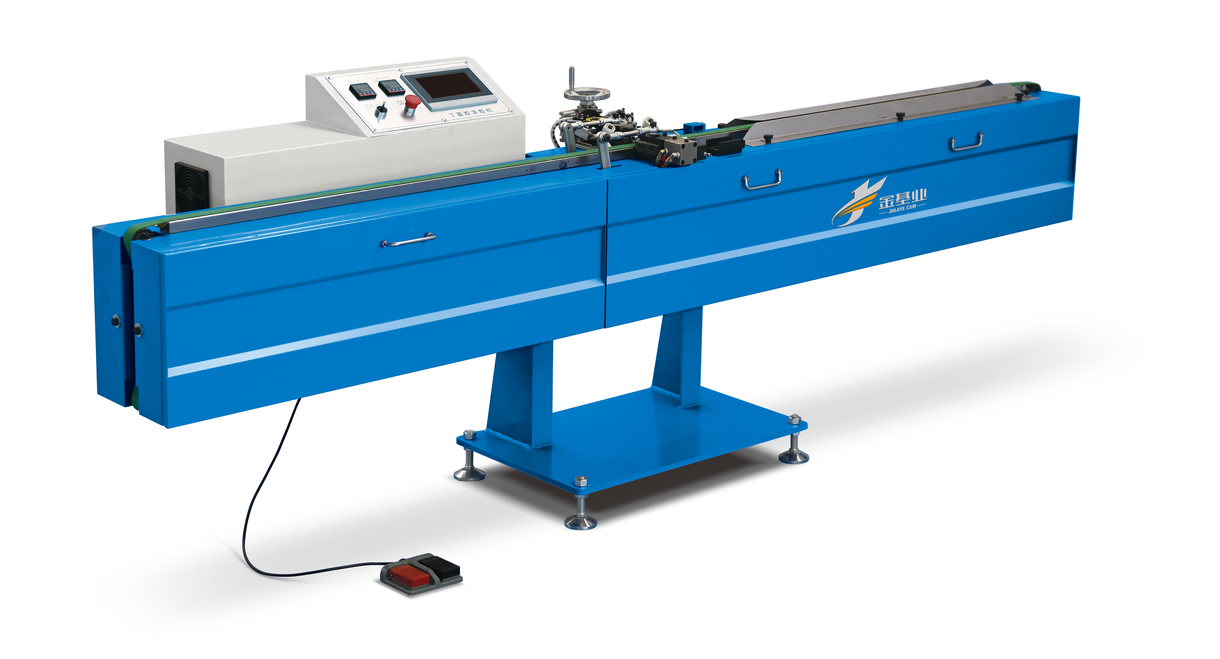

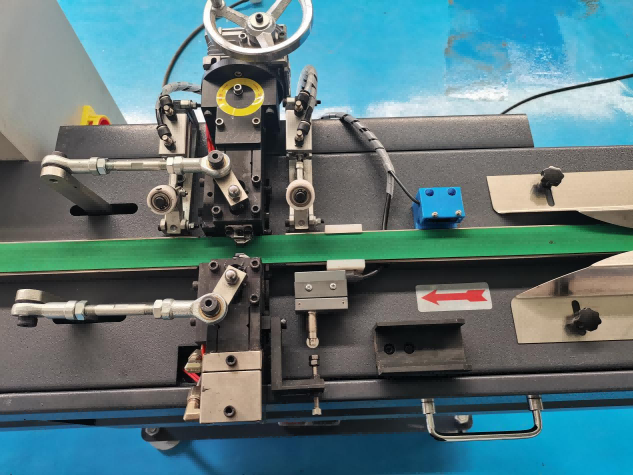

Automatic Butyl Sealant Extruder Machine

1. This machine is suitable for the coating process of butyl rubber for insulating glass aluminum spacer.

2. In order to keep the stable glue output performance,advanced gas-liquid pressurization technology is adopt.

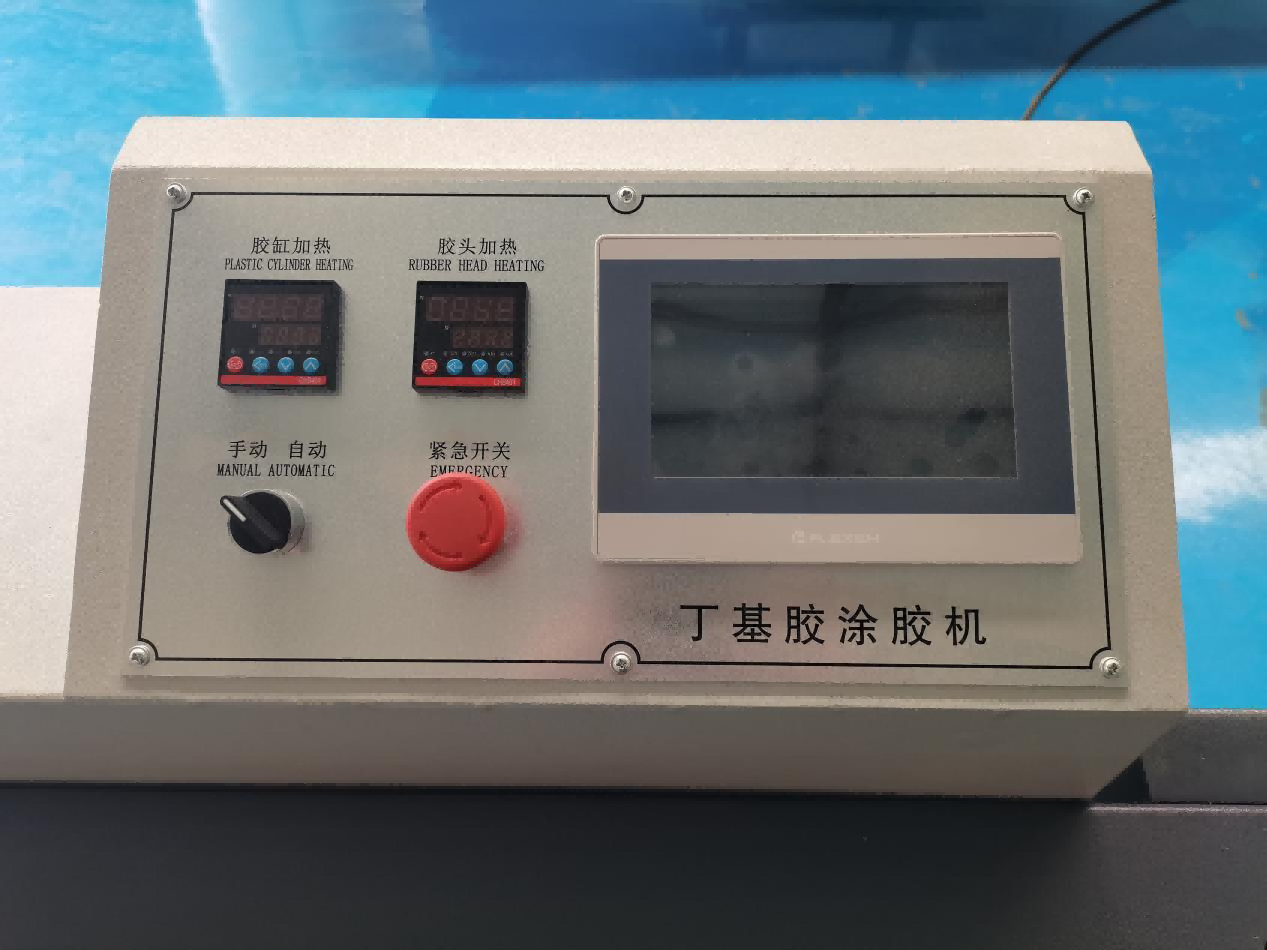

3. Touch screen temperature control ,high precious,simple operation.

4. The whole structure is modular ,with low failure rate and easy maintenance.

Automatic Butyl Sealant Extruder Machine. It has the following advantages and performance: 1.Introduction of The Product

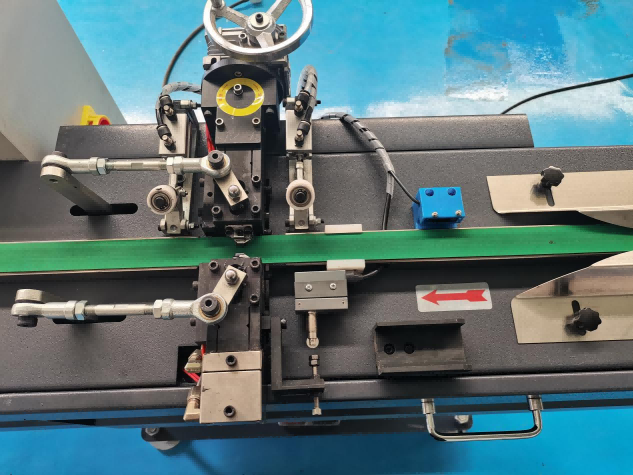

This machine has 5-speed transmission control function.Real-time instrument display of glue quantity,early warning .The width of the rubber nozzle can be automatically adjusted by induction ,which can quickly locate.The mount of butyl rubber is 14kgs ,and the width of processed aluminum strip is 4-30mm.Automatic refueling of fuel tank is clean and labor-saving.

2.Product Parameter Table

Voltage | 380V/50Hz |

Glue spreading pressure | 12-18Mpa |

Adjustable range of extruding nozzle | 6-27mm |

Rubber bucket capacity | 14kg |

Total power | 4.0Kw |

Atmospheric pressure | ≥0.6Mpa |

Glue spreading speed | 18-40m/min |

Width of aluminum strip | 4-30mm |

Glue coating temperature | 110-160℃ |

Overall dimension | 3000*700*900mm |

3.Product Packaging