The Power Behind Perfect Glass: Revolution of Modern Glass Processing Machines

In the fast-evolving world of architecture and construction, glass has become more than a building material—it’s a statement of innovation, elegance, and sustainability. From skyscrapers that gleam under the sun to energy-efficient homes filled with natural light, modern glass defines how we live and build today.

But behind every flawless glass panel lies a story of precision, automation, and cutting-edge technology—the story of glass processing machines.

1. Precision Begins with Cutting

The journey of every glass sheet starts at the cutting table. Modern glass cutting machines transform raw glass into perfectly dimensioned panels with micron-level accuracy.

Gone are the days of manual scoring and uneven edges. Today’s automatic cutting lines use computer-controlled systems (CNC) to ensure every cut is smooth, efficient, and waste-free.

High-speed cutters with intelligent nesting software minimize material loss, while automatic loading and breaking tables make the process fast and safe.

For manufacturers, this means higher yield, faster production, and lower cost—a win from every angle.

2. Flawless Finishing with Edging and Grinding

Once the glass is cut, edging and grinding machines take over to refine the edges. This step not only enhances safety but also elevates the visual quality of the final product.

Modern double-edge grinding lines can handle multiple sizes and thicknesses automatically, ensuring perfect parallelism and consistent polishing.

Advanced features like automatic thickness detection and servo-controlled spindles guarantee a finish that meets even the most demanding architectural standards.

3. Clarity through Cleaning: The Role of Glass Washing Machines

Before glass enters the next stage, cleanliness is crucial.

Glass washing machines use soft brushes, stainless steel structures, and high-efficiency blowers to ensure the glass is spotless and ready for coating, lamination, or assembly.

In insulated glass production, washing quality determines sealing performance and long-term durability. A single dust particle can ruin an entire panel—this is why precision washing is the unsung hero of every production line.

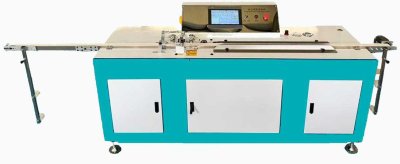

4. The Heart of Insulating Glass: Butyl Extruder and Spacer Line

When it comes to energy-efficient windows, insulating glass (IG) is the gold standard—and the butyl extruder is its beating heart.

This machine applies a uniform layer of butyl sealant on aluminum spacers, creating the airtight seal that keeps double-glazed units performing for decades.

High-speed, fully automatic butyl extruders ensure consistent coating, minimal waste, and perfect adhesion, directly improving insulation performance and energy savings.

Working alongside are aluminum spacer bending machines and desiccant filling machines—both vital in IGU (Insulating Glass Unit) production.

The bending machine shapes spacers with absolute precision, ensuring tight corner angles without leaks, while the desiccant filler keeps moisture out, preventing fogging and maintaining optical clarity.

Together, these machines form the backbone of modern insulating glass lines, combining efficiency, accuracy, and durability.

5. Automation and Smart Control: The Future of Glass Processing

Today’s glass factories are embracing Industry 4.0, where machines communicate seamlessly through intelligent control systems.

Touchscreen interfaces, data monitoring, and automatic diagnostics help operators maintain top performance with minimal downtime.

From glass storage to final assembly, a smart production line can now operate with less labor, more consistency, and 24/7 reliability.

6. Why Investing in Modern Machines Matters

For any glass manufacturer or construction supplier, upgrading to advanced glass processing equipment is not just about technology—it’s about competitiveness and sustainability.

Modern machines reduce energy consumption, enhance precision, and support eco-friendly production.

With global demand rising for low-emissivity (Low-E) and high-performance glazing, having the right machines positions your business at the forefront of the market.

7. Partner with the Experts in Glass Machinery

Behind every strong machine is a strong manufacturer. Choosing the right partner ensures not just quality equipment but also training, maintenance, and lifetime service support.

Whether it’s a fully automated insulating glass line, CNC cutting table, or high-efficiency washing machine, reliable suppliers help you build smarter, produce faster, and deliver better glass—every time.

Conclusion: Shaping the Future of Glass

The modern world’s transparent beauty is built on precision engineering.

From the first cut to the final seal, glass processing machines enable the brilliance, strength, and sustainability that define today’s architecture.

As technology continues to evolve, automation and innovation will further transform how we produce and use glass—turning every window, facade, and partition into a symbol of progress.