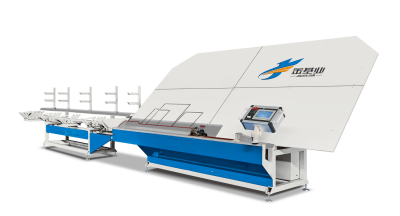

Anyone in the insulating glass (IG) business knows that buying an Automatic Molecular Sieve Filler isn’t just a purchase—it’s a bet on your factory’s future. This machine does more than just fill spacer bars with sieve; it directly determines how fast you can produce glass, how much Automatic Molecular Sieve you’ll waste, and whether you’ll be stuck working overtime on a Friday afternoon fixing foggy defective glass units.

But here’s the problem: Most suppliers are all talk. They’ll show you flashy brochures, throw around terms like “high efficiency and energy saving,” and act like their filler is the only one worth buying. I’ve seen too many people fall for this—only to end up with a machine that clogs every hour or wastes Automatic Molecular Sieve like it’s free.

The solution? Stop listening to the hype. Start asking real, tough questions. Below are 5 questions you must ask every supplier before writing a check. Each one is based on real mistakes I’ve seen factories make—mistakes that cost them tens of thousands of dollars.

1. “What’s the Actual Filling Accuracy? ‘Close Enough’ Will Ruin My Glass!”

Here’s a truth suppliers won’t volunteer: Most cheap Automatic Molecular Sieve Filler models have inconsistent accuracy. I had a client who bought a filler that claimed “±1g precision.” What happened? Half the spacer bars got 0.5g too little sieve—all the glass fogged up. The other half got 0.5g too much—the sealant popped right off. Not only did customers return orders, but he also had to pay penalty fees. Total disaster.

Don’t settle for vague claims. Grill them:

“If a spacer bar is underfilled, will the filler reject it automatically, or let it move to the next process? I don’t have time to rework 100 defective units, and missed deadlines are even worse.”

The best Automatic Molecular Sieve Filler models hit ±0.3g every time, with real-time weight checks to ensure consistency. I know a factory that switched to one, and their foggy glass return rate dropped from 15% to 2—saving them tens of thousands in rework costs alone. If a supplier can’t give you a specific number, or fudges it with “industry average,” walk away—they don’t have the confidence in their product.

2. “How Hard Is This Thing to Clean? My Team Isn’t Made of Engineers.”

80% of the Automatic Molecular Sieve Filler breakdowns I’ve seen aren’t from bad parts—they’re from poor maintenance. Automatic Molecular Sieve residue clogs nozzles, dust coats sensors, and suddenly the machine goes haywire: either it won’t fill at all, or it fills unevenly. One factory’s filler took 2 hours to clean; workers got tired of doing it properly, and after just 6 months, the nozzle was completely blocked. Replacing it plus repair fees cost them $1,800.

So ask suppliers about the “unglamorous” but critical stuff—cleaning and maintenance:

“Will you send someone to train my team in person? The last supplier just sent a 100-page English manual; my workers couldn’t understand it, and when the machine broke, they had no idea how to fix it.”

Good fillers have automatic cleaning functions—rinse it before startup, and any leftover Automatic Molecular Sieve in the hoses is gone. Cleaning takes just 15 minutes. They also come with basic tool kits, and suppliers will send a technician to train your team in person—all of which should be in writing in the contract. If a supplier just says “maintenance is easy” but won’t explain how or if it costs extra, they’re setting you up for trouble.

3. “How Long Will It Take to Fix If It Breaks? I Can’t Wait 3 or 5 Days.”

This is the most overlooked trap! A client of mine bought an Automatic Molecular Sieve Filler that seized up after just 3 months—the motor wouldn’t run. He called the supplier, who said, “Our technician is out of town; we can send someone next week.” His production line was down for 5 days, he missed order deadlines, and had to pay an $8,000 penalty to his customer. That loss was more than the cost of the machine itself.

So you must get clear on after-sales response times—don’t fall for empty lines like “our after-sales service is great”:

“If the machine breaks in the middle of the night, can you provide remote troubleshooting? If remote fixes don’t work, how soon can you send a technician to my location in [City Name]? Don’t tell me ‘it depends on distance’—give me a specific time.”

Reliable suppliers will say, “24/7 remote support, on-site technicians within 24 hours for local customers, and common parts shipped within 3 days”—and they’ll put this in the after-sales agreement. If a supplier hesitates and says “we’ll try our best” or “it depends,” move on—they don’t have the capacity to fix issues quickly.

4. “Will This Machine Work With My Production Line? Don’t Let Me Buy Something That Won’t Fit.”

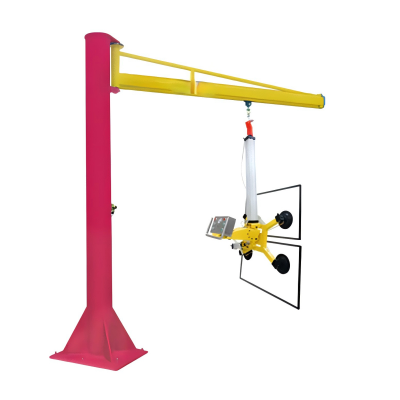

The most ridiculous thing I’ve ever seen: A factory bought an Automatic Molecular Sieve Filler that was too tall to fit through their workshop door. They finally got it in by removing the door, only to find it didn’t connect to their upstream spacer cutter or downstream butyl coater. They had to spend extra money modifying their production line—half the cost of the filler itself. All because they didn’t ask about compatibility.

So be clear with suppliers about your production line, then ask:

Professional suppliers will first ask about your line’s size, speed, and supporting equipment brands, then recommend a compatible model. Some will even send an engineer to measure your workshop in person. If a supplier doesn’t ask about your production line at all and just says “it’ll definitely fit,” they’re lying.

5. “How Much Automatic Molecular Sieve Will This Machine Save Me? Show Me the Numbers.”

Automatic Molecular Sieve isn’t cheap—it’s easily \(3–\)4 per pound. Even wasting just 5% adds up fast over a year. I had a client who wasted 12% of his Automatic Molecular Sieve with manual filling—costing him an extra $12,000 a year. He switched to a good Automatic Molecular Sieve Filler, and now his waste rate is just 1%—the machine paid for itself in 2 years.

So make suppliers crunch the numbers for you—don’t accept vague claims like “it’ll save a lot”:

Reliable suppliers will grab a calculator and walk you through it: “If we cut your waste to 2%, you’ll save \(2,400 a year. With a \)40,000 machine, that’s a 16-month payback.” They’ll even show you data from other customers. If a supplier can’t calculate this, or says “it’s impossible to know,” they either don’t understand their product or know it won’t save you much—so they’re hiding the truth.

Final Thought: Don’t Be Afraid to Be Picky

Buying an Automatic Molecular Sieve Filler is one of the most important decisions you’ll make for your factory. Choose the right one, and you’ll save time, money, and headaches. Choose the wrong one, and you’ll be tempted to throw a hammer at it.

Suppliers who get annoyed by your questions? They’re not worth working with. Those who answer openly, show you data, and visit your workshop to assess your needs? Those are the ones to trust.

Remember: Every question you ask is protecting your business. Don’t skip any. Don’t worry about offending suppliers—your bottom line and your production line are more important than being “polite.”