What to Look for When Buying an Automatic Molecular Sieve Filler for Insulating Glass

2025/10/31 13:42

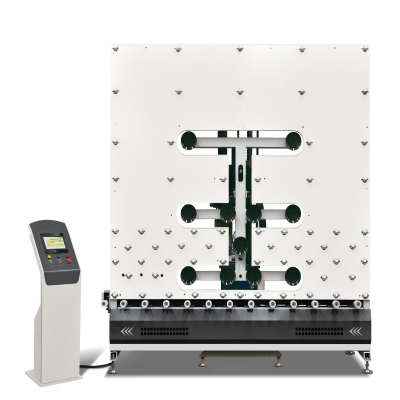

If you’re in the insulating glass (IG) game, you know this much: buying an Automatic Molecular Sieve Filler isn’t something you rush. I’ve helped clients pick out over 20 of these machines, and the ones who screwed up? They all skipped the basics. This thing isn’t just a hunk of metal on your floor—it decides how fast you crank out glass, how many bad units you toss in the trash, and whether you actually make money at the end of the month.

The market’s a total mess right now. Every seller’s yelling their filler’s the best—“Fastest on the market!” “Cheapest deal!”—but specs on a sheet? They don’t tell you squat. I had a guy last year buy a “top-of-the-line” model just ‘cause it had a touchscreen and fancy lights. Turned out it couldn’t handle his usual 300mm spacer bars. Wasted $40k right there.

Here’s the real talk: the right Automatic Molecular Sieve Filler isn’t the fanciest one. It’s the one that fits your shop. Do you mostly make small residential glass for homes? Or big commercial panels for office buildings? Do you have a tight budget, or can you spend a little more on something that’ll last? Those are the questions that actually matter.

Below, I’ll break down four things you have to check before you sign a check. Plus, how to talk to an Automatic Molecular Sieve Filler Manufacturer so you don’t get sold a lemon.

1. First, Check: Can the Machine Handle Your Spacer Bars and Sieve? (Don’t Believe “One-Size-Fits-All” Lies)

I’ve seen way too many factories rush into buying a filler ‘cause the sales guy said, “This thing works with any size.” Then they unbox it, hook it up, and—surprise—it’s useless. One client of mine made 300mm small bars and 2000mm big ones. The machine he bought only handled 500-1500mm. Ended up having two guys filling the small/big bars by hand. What’s the point of automatic if you still need manual labor?

And let’s talk sieve—we all use 0.5-0.9mm diameter stuff, right? But some fillers get clogged up with 0.3mm fine sieve like it’s a pipe full of mud. Others leak 1.2mm coarse sieve all over the floor. Nothing kills a production day faster than stopping everything to unclog a nozzle or sweep up wasted sieve.

So before you buy, spell out your needs to the Automatic Molecular Sieve Filler Manufacturer. Tell ‘em the smallest/largest bars you use, the sieve brand you stick with, and its particle size. Even better—ask for a “compatibility test.” Send ‘em samples of your bars and sieve, and make ‘em demo how the machine handles ‘em. Good manufacturers will say, “We can tweak the nozzle/hopper for you.” Shady ones? They just keep saying, “Trust me, it’ll work.” Also, think ahead: if you plan to take on big projects (like glass for skyscrapers), get a machine that can be upgraded. Otherwise, you’ll be buying a new one in two years—and that’s just throwing cash away.

2. Precision and Stability Matter More Than Anything (“Close Enough” Will Cost You Big Time)

Some bosses think, “A little error in sieve filling? No big deal.” Big mistake. I had a client buy a cheap filler with ±1g precision. Six months later, he was reworking foggy glass left and right—‘cause the machine underfilled half the bars. Wasted sieve from overfilling the other half. Ended up losing over $30k in rework and materials.

So when you’re looking at an Automatic Molecular Sieve Filler, aim for at least ±0.5g precision. Even better—make the manufacturer show you third-party test reports. Like, proof that the machine stays within ±0.3g error for 1,000 fills in a row. That way, you know it won’t get sloppy after a few weeks.

Stability’s just as important. I’ve seen machines work great for the first 100 bars, then slow down or start filling unevenly after 3 hours. Imagine you’re rushing to meet a big order deadline, and the filler dies on you. Your workers are standing around, the client’s blowing up your phone—total nightmare. So ask the Automatic Molecular Sieve Filler Manufacturer: “Can this thing keep speed and precision up for 8+ hours straight?” Get actual numbers, not just “Yeah, it’s stable.” And check for self-check features—like alerts if it underfills, or auto-rejects bad bars. Those small things save you so much hassle.

3. Don’t Ignore After-Sales Support (A Machine Without Service Is Worse Than No Machine)

Lots of people only look at the Automatic Molecular Sieve Filler - Price and grab the cheapest one. Bad move. I had a guy buy a \(35k filler last year. Broke after three months. Called the manufacturer—they said, “We can send a tech next week.” His line was down for five days. Lost over \)10k in orders.

So before you buy, ask the Automatic Molecular Sieve Filler Manufacturer three non-negotiable questions:

First: How fast can you fix issues? Get a manufacturer with 24/7 support. Someone you can call at midnight if the machine craps out. If remote fixes don’t work, they should send a tech within 1-2 days. Avoid brands that only answer phones on weekdays—we in manufacturing work shifts, weekends included.

Second: What’s included in maintenance? Good companies offer free annual check-ups. Train your workers to fix small stuff—like cleaning nozzles or replacing filters. Even throw in a spare parts kit. Ask, “How long will this machine last?” A good one should go 7-10 years with care. Cheap ones? 3-4 years max.

Third: Can you update the software later? IG standards change fast—new energy rules, tighter specs. You might need to tweak the filler’s settings. If the manufacturer offers free software updates for 3-5 years, you won’t have to buy a new machine. Some Automatic Molecular Sieve Filler Manufacturers do this—total money-saver.

Remember: Don’t just count the upfront cost. A machine with bad support will cost you way more in the long run.

4. Calculate Total Cost of Ownership (Don’t Just Look at the Initial Price Tag)

Too many bosses see a price tag—\(40k for Machine A, \)50k for Machine B—and think A’s cheaper. Wrong. You gotta calculate “total cost of ownership (TCO)” over 5 years. That includes three big things:

Electricity: Some fillers use 1.5kW/hour, others 1kW. At \(0.15/kWh, a 1.5kW machine costs \)2k more a year. Over 5 years? $10k extra. Ask the manufacturer, “How much juice does this thing use?” and do the math based on your hours.

Sieve waste: If Machine A wastes 10% of sieve, Machine B only 2%, and you use 1,000kg a year (\(3/kg), A costs \)2,400 more annually. 5 years? \(12k. I did this math for a client—he bought B, which was \)10k more upfront, but saved $12k on sieve alone. No-brainer.

Labor savings: A good Automatic Molecular Sieve Filler replaces 1-2 workers. If you pay \(25/hour, replacing two saves \)100k a year. Even if the machine’s $30k more, it pays for itself in 4 months.

So make the Automatic Molecular Sieve Filler Manufacturer help you calculate TCO. Good ones will make you a simple table—“This machine costs \(75k total over 5 years, \)30k less than the cheap one.” No guesswork.

Final Thought: Take Your Time—Compare and Test Before You Buy

Buying an Automatic Molecular Sieve Filler isn’t like grabbing milk at the store. You can’t just pick one and go. Do this: list your needs first (bar sizes, how much you make, budget). Then talk to 2-3 good Automatic Molecular Sieve Filler Manufacturers. Ask for proposals, test their machines, even visit their clients’ shops to see ‘em in action.

The best machine for you isn’t the cheapest or the flashiest. It’s the one that keeps you from reworking glass, doesn’t waste sieve, and stays running. Don’t let sales guys pressure you into a quick buy. Ask questions, test everything, do the math—and you’ll end up with a machine that actually makes you money.