How Does an Automatic Molecular Sieve Filler Improve Production Efficiency

2025/10/30 10:43

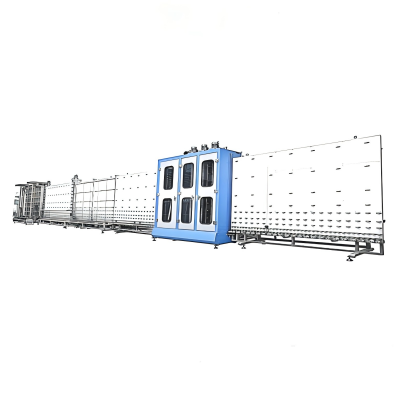

If you’re in insulating glass (IG) manufacturing, you know the drill: every minute your line’s stuck, every wasted bag of sieve, eats into profits. For years, manual molecular sieve filling was the biggest headache—slow, messy, and you always needed someone with steady hands. Then the Full-Automatic Molecular Sieve Filling Machine came along. This thing isn’t just a “filler”—it’s a game-changer for how you run your shop. It cuts waste, speeds up work, and stops those little human mistakes that add up. Below, I’ll break down three key ways it boosts efficiency—plus how to pick the right one from a solid Automatic Molecular Sieve Filler Manufacturer.

1. Eliminates Manual Labor Bottlenecks (and Cuts Labor Costs)

Let’s be honest: manual sieve filling is a slog. A good worker might do 20-30 aluminum spacer bars an hour, but by the end of the shift? They’re tired, so they slow down. Or they rush and mess up the filling. Either way, your whole line gets held up—even if your cutter or sealant machine is chugging along fast.

The Full-Automatic Molecular Sieve Filling Machine fixes that. It handles everything from storing sieve to pouring it exactly right—no person needed. The top models? They can do 80-120 bars an hour. I know a mid-sized shop in Michigan that swapped two full-time fillers for one of these machines. Their hourly output went from 50 bars to 110. That’s a huge jump.

And let’s talk money: you don’t have to hire, train, or pay someone just to fill sieves anymore. You can move that worker to a job that actually helps your business grow—like checking quality or fixing machines. When you talk to an Automatic Molecular Sieve Filler Manufacturer, ask about the controls. The best Full-Auto Molecular Sieve Filling Equipment lets you set bar size or sieve amount in minutes. Even new hires can run it—no years of experience needed. That means you won’t lose time if someone quits.

2. Cuts Sieve Waste (And Sieve Isn’t Cheap)

Molecular sieve costs a pretty penny. With manual filling? You’re throwing money away. Workers spill it on the floor, overfill bars to “make sure,” or toss half-used batches because they’re scared it got wet. I’ve seen shops waste 10-15% of their sieve every month. That’s thousands of dollars gone—for nothing.

The Full-Automatic Molecular Sieve Filling Machine stops that waste cold. It uses weight sensors and simple programming to pour exactly what each bar needs. No more, no less. A lot of models even have a system that catches extra sieve and reuses it. One factory in Ohio told me they went from wasting 12% of their sieve to just 2% after getting this machine. That’s over $3,000 saved a year on sieve alone.

When you’re picking an Automatic Molecular Sieve Filler Manufacturer, ask for their waste numbers. The good ones will have proof—like third-party tests showing their machines use 98% of the sieve. That means almost every gram goes into your product, not the trash. It’s not just saving money—it’s better for your bottom line, too.

3. Reduces Downtime (Keeps Your Line Running)

Manual filling means unexpected stops. A worker calls in sick? You can’t fill bars. A bag of sieve gets wet? You have to stop to replace it. Even a 10-minute break can throw off your whole schedule. And if you’re late on an order? That’s an unhappy customer.

The Full-Automatic Molecular Sieve Filling Machine keeps your line going. First, it has a big hopper—holds 50-100kg of sieve. You don’t have to refill it every hour. Second, it has sensors that tell you when sieve is low—via an app or screen. You can refill it during a scheduled break, not in the middle of production. Third, it’s simple—fewer parts to break. One manufacturer told me their machine has a 99% uptime rate. It only stops for planned maintenance.

When you choose an Automatic Molecular Sieve Filler Manufacturer, ask about support. The best ones offer 24/7 help, fast parts delivery, and regular check-ups. If your Full-Auto Molecular Sieve Filling Equipment breaks, they’ll fix it quick. One shop I know had a problem at 2 AM—they called support, and the issue was fixed remotely in 30 minutes. No costly on-site visits, no lost production.

Final Thoughts: This Machine Changes How You Work

For IG shops, efficiency isn’t just about speed—it’s about doing things right, saving money, and growing. The Full-Automatic Molecular Sieve Filling Machine does all three. It cuts labor costs, wastes less sieve, and keeps running. Whether you’re a small shop trying to take on bigger orders or a big factory wanting to optimize, this machine is a must.

To get the most out of it, partner with a good Automatic Molecular Sieve Filler Manufacturer—one that sells Full-Auto Molecular Sieve Filling Equipment with the features you need, and backs it up with support. With the right machine, that slow, messy filling step becomes the fastest part of your line.

Don’t let manual filling hold you back. Get a Full-Automatic Molecular Sieve Filling Machine—you’ll wonder how you ever ran your shop without it.