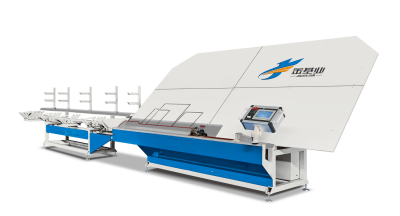

The Precision BehinPerfect Insulating Glass: Aluminium Spacer Bending Machine

In the world of insulating glass (IGU) production, every detail matters. The strength, appearance, and energy efficiency of an IG unit depend greatly on one small but critical component — the aluminium spacer.

And the key to producing these spacers with perfect accuracy and consistency lies in one powerful machine: the Aluminium Spacer Bending Machine.

1. What Is an Aluminium Spacer and Why It Matters

In double or triple-glazed insulating glass, the aluminium spacer sits between two panes of glass, creating the air or gas-filled space that provides thermal insulation.

This small frame must be perfectly sealed, precisely measured, and completely straight. Any mistake in its shape can lead to leaks, fogging, or poor insulation.

That’s why manufacturers worldwide rely on automatic spacer bending machines — to make sure every spacer frame is strong, accurate, and airtight.

2. From Manual to Automatic: A Revolution in Spacer Production

In the past, spacers were cut and joined manually using corner keys — a process that was slow, inconsistent, and wasteful.

Modern automatic aluminium spacer bending machines have completely changed this process.

They use CNC computer control to automatically feed, cut, and bend the spacer from a continuous coil of aluminium strip — in just a few seconds, the machine delivers a complete rectangular or shaped frame with precise corners and perfect alignment.

This innovation eliminates manual work and ensures high accuracy and consistency, even for complex glass sizes.

3. How the Spacer Bending Machine Works

The process is fast, smooth, and fully automatic:

Automatic Loading – The machine automatically loads the aluminium spacer bar or coil.

Measurement & Cutting – Using pre-programmed sizes, it measures and cuts exactly as required.

Smart Bending – High-precision servo motors bend the spacer at perfect 90° angles (or custom shapes).

Automatic Connection – The machine completes the frame without needing corner keys, ensuring strong and seamless joints.

The result: a perfectly formed spacer frame that fits exactly into the insulating glass unit — strong, beautiful, and airtight.

4. Key Advantages of Aluminium Spacer Bending Machines

✅ High Precision – Servo control ensures accurate bending and consistent angles every time.

✅ Fast Speed – Complete a spacer frame in just a few seconds — ideal for mass production.

✅ No Corner Keys Needed – Reduces material cost and improves sealing strength.

✅ Less Waste – Continuous feeding means maximum use of each aluminium coil.

✅ Multi-Size Compatibility – Can bend spacers in various widths and lengths automatically.

✅ User-Friendly Interface – Touch screen operation and automatic data input make setup simple.

✅ Stable & Durable – Built with heavy-duty frames and reliable control systems for long life and low maintenance.

5. The Role in Insulating Glass Production Lines

The aluminium spacer bending machine is a key part of the insulating glass (IG) line, working together with:

Butyl Extruder Machine – applies butyl sealant onto the spacer,

Desiccant Filling Machine – fills moisture-absorbing material inside the spacer,

Glass Assembly and Press Machine – assembles and seals the IG unit.

When combined, these machines create a fully automated, high-efficiency IG production system that delivers premium quality glass for windows, facades, and curtain walls.

6. Why It’s Essential for Modern Manufacturers

In the competitive glass industry, speed, accuracy, and energy efficiency are everything.

Using an aluminium spacer bending machine helps manufacturers:

Increase production capacity

Improve product quality and appearance

Reduce labor and waste costs

Meet international energy-saving standards

It’s not just a machine — it’s a long-term investment that brings reliability, consistency, and professional image to your glass business.

7. Building the Future of Energy-Efficient Glass

As the world moves toward green, energy-saving buildings, insulating glass with perfect spacers becomes more important than ever.

With an aluminium spacer bending machine, glass manufacturers can meet strict quality requirements and deliver products that last longer, perform better, and save more energy.

Whether you produce glass for residential windows, commercial buildings, or architectural facades, this machine ensures that every piece of glass meets the highest global standards.

Conclusion: Precision Shapes Perfection

The Aluminium Spacer Bending Machine is not just a tool — it’s the foundation of modern insulating glass production.

It combines speed, accuracy, and automation to turn aluminium strips into high-performance spacer frames that define the quality of every IG unit.

Investing in this machine means investing in quality, efficiency, and the future of glass manufacturing.