Company News

A glass cutting machine is the first “make-or-break” step in most flat-glass factories. When the cutting stage is stable, everything downstream—edging, washing, tempering, lamination—runs smoother. When it isn’t, scrap rises, edge defects appear, and operators spend the day chasing inconsistencies

2026/02/02 15:52

In channel-type insulated glass production lines, the desiccant filling step is easily overlooked—until issues like haze, fogging, or edge seal problems arise. The fully automatic molecular sieve filling machine (also called a molecular sieve filler) is designed to make this step consistent, clean

2026/01/31 10:38

Sealing performance depends on more than sealant quality. Spacer frame geometry plays a direct role in how sealants behave over time. An hAutomatic Aluminum Spacer Bending Machine elps create uniform frames that support reliable sealing.Poorly bent corners or uneven frame sides can cause sealant

2026/01/19 13:42

Daily production stability is one of the biggest challenges in insulating glass factories. Even small fluctuations in spacer frame quality can slow down the entire line. An Automatic Aluminum Spacer Bending Machine helps maintain consistent output without relying on manual adjustments.Manual

2026/01/12 15:35

Equipment selection should always be based on long-term performance rather than short-term cost. This is especially true for primary sealing equipment. A Full Automatic Butyl Extruder offers advantages that extend well beyond automation.An Automatic Butyl Extruder Machine ensures stable output by

2026/01/06 10:44

Primary sealing is the first physical barrier protecting insulating glass from moisture intrusion. If this step is unstable, no secondary sealant can fully compensate for it. An Automatic Butyl Coating Machine is designed specifically to address this issue.Unlike traditional coating methods,

2025/12/31 10:32

In insulating glass production, errors rarely come from a single major mistake. Most quality problems develop gradually from small inconsistencies during primary sealing. This is where a Full Automatic Butyl Extruder plays an important role.Manual coating depends heavily on operator skill and

2025/12/24 09:28

In many insulating glass factories, the primary sealing process is still treated as a supporting step rather than a critical operation. However, long-term field performance shows that unstable primary sealing is often the root cause of moisture penetration and IGU failure. This is why more

2025/12/17 14:21

Glass is everywhere — in buildings, windows, doors, and decoration. It brings light, beauty, and comfort to our lives. But high-quality glass doesn’t happen by chance. It’s made by advanced glass processing machines that ensure every piece is perfect, safe, and long-lasting.1. Cutting: The First

2025/10/18 13:47

In the fast-evolving world of architecture and construction, glass has become more than a building material—it’s a statement of innovation, elegance, and sustainability. From skyscrapers that gleam under the sun to energy-efficient homes filled with natural light, modern glass defines how we live

2025/10/18 13:30

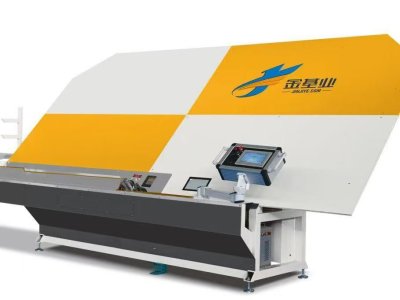

Glass cutting machine refers to a processing machine specially used for glass processing and cutting. The glass cutting machine includes an air floating feeding table arranged at the end and a double-bridge overpass cutting table. As an improvement, the double-bridge overpass cutting table is

2024/07/25 10:04

The insulating glass production line is mainly composed of four parts: feeding section, cleaning and drying section, inspection section and sealing section. Each part is placed vertically with the same inclination Angle, compact structure, convenient maintenance, and improve production efficiency.

2024/07/23 16:19