Automatic Molecular Sieve Filler for Insulating Glass: Why It’s a Must-Have

2025/10/29 10:47

Insulating glass (IG) is everywhere these days. New homes, office buildings, even the storefront down the street—you’ll see it. And for good reason: it keeps rooms warm when it’s cold, cool when it’s hot, and drowns out the noise from outside. But here’s the thing I always tell people: a good IG unit isn’t just put together. You’ve got to fill that aluminum spacer bar with molecular sieve. It’s a desiccant—soaks up moisture and the leftover gunk from manufacturing. Skip this step, or do it sloppy? The glass fogs up fast, cracks easy, or stops insulating like it should.

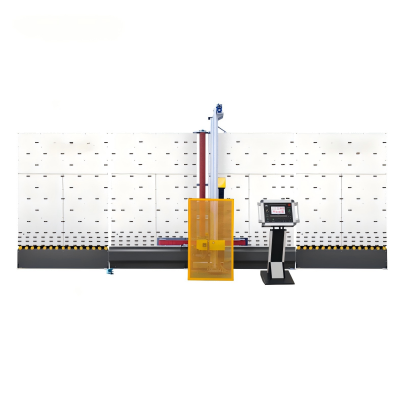

A few years back, most shops did this by hand. Scooping sieve into the bars, hoping for the best. But now? If you’re making IG seriously, the Automatic Molecular Sieve Filler isn’t optional. I’ve talked to dozens of IGU manufacturers—small shops, big factories, all of them. Every single one that switched to automatic filling says they’d never go back. Below are the four biggest reasons why. Plus, how to pick the right setup from a solid Automatic Molecular Sieve Filler Manufacturer.

1. No More Defects—Your IG Units Stay Consistent (and Profitable)

Manual filling is a gamble. I once visited a small shop where a worker spilled a whole bag of sieve on the floor. Panicked, he dumped extra into the next batch of spacer bars to make up for it. You guess the rest: half those IG units fogged up in six months. The shop had to replace them for free—cost them a ton.

An Automatic Molecular Sieve Filler takes that guesswork out. It uses simple sensors and programming to put exactly the right amount of sieve in every bar. Doesn’t matter if the bar’s 300mm tiny or 2000mm huge—it’s precise. I know a mid-sized factory in Ohio that switched to automatic. Their defect rate dropped from 8% to less than 1%. That’s thousands saved on rework and wasted glass.

When you talk to an Automatic Molecular Sieve Filler Manufacturer, ask about extra features. Like alerts that pop up if something’s off. One manufacturer I work with adds a small camera to their fillers. You can check if the sieve’s spread evenly without stopping production. Little touches like that make the Automatic Molecular Sieve Filler worth every penny.

2. You’ll Make More IG Units (Without Hiring More People)

Let’s be real: manual filling is slow. A good worker might knock out 20-30 spacer bars an hour. But what if you get a big order? Say 500 IG units for a new apartment building. That pace won’t cut it. I’ve seen shops turn down jobs because they couldn’t keep up with hand filling.

An Automatic Molecular Sieve Filler changes that. Most models handle 50-100 bars an hour—sometimes more if you get a fast one. And if you want to really speed things up? Look into a Full-Automatic Molecular Sieve Filling System. These hook up to your other machines—like the one that cuts spacer bars or puts on sealant. The whole process runs without anyone touching it. A shop in Texas told me they went from 150 IG units a day to 350 after installing one. No new hires—just better equipment.

For small shops, that means taking on bigger orders. For larger ones, no extra shifts. Either way, the Automatic Molecular Sieve Filler helps you make more money.

3. You’ll Waste Less Sieve (And Sieve Isn’t Cheap)

Molecular sieve isn’t free. It’s about \(2-\)3 a pound, depending on the type. Spill a little every day? It adds up fast. I worked with a shop once that wasted nearly 10 pounds a week on manual filling. Spills, overfills, sieve that fell on the floor and got dirty. That’s over $1,000 a year down the drain.

An Automatic Molecular Sieve Filler stops that waste. It only uses what it needs. And most models have a little system that catches extra sieve and reuses it. I know a manufacturer in Indiana that cut their sieve use by 18% with an automatic filler. Over a year, that’s $2,500 saved—enough to cover half the cost of the filler itself.

When you chat with an Automatic Molecular Sieve Filler Manufacturer, ask about their waste rate. The good ones will give you a straight number—like “our fillers waste less than 2% of sieve.” Steer clear of ones that can’t back it up with real data. And don’t forget labor savings: if you don’t need someone filling sieves all day, move that worker to a job that actually grows the business.

4. You’ll Keep Up With New Rules (And Win More Clients)

The IG industry has strict rules now. Groups like ISO and AAMA say IG units should last at least 20 years. Good luck hitting that with manual filling. If the sieve’s not even, the unit fails early. And more clients these days? They want proof your IG meets those standards before they order.

An Automatic Molecular Sieve Filler helps you check that box. Its precise filling makes sure the sieve works right—so your IG units last decades. And if rules change? A lot of Full-Automatic Molecular Sieve Filling System models can be updated. Like a few years back, when eco-friendly sieves got popular. One manufacturer I know sent out a simple software update—no new machine needed.

Choosing the right Automatic Molecular Sieve Filler Manufacturer matters here. Look for ones that follow industry trends. A good one will say, “Hey, we added a feature for the new energy standards” instead of selling you a machine that’s outdated in two years. One client of mine switched to a manufacturer that offers free updates for three years. They haven’t bought new equipment since 2021—even with all the new rules.

Final Thoughts: Stop Waiting—Get an Automatic Filler

If you’re still filling molecular sieve by hand, you’re holding your business back. The Automatic Molecular Sieve Filler makes your IG units better, faster, and cheaper to make. I’ve seen shops of all sizes grow because they invested in one.

Find a reliable Automatic Molecular Sieve Filler Manufacturer. Ask for references, check their defect rates, and make sure they help you if something breaks. If you can afford it, a Full-Automatic Molecular Sieve Filling System is even better. But even a basic automatic filler will change the game.

Don’t let manual filling cost you orders, money, or clients. Get an Automatic Molecular Sieve Filler this year—you’ll wonder how you ever worked without it.