Top Hollow Glass Production Lines for Your Company

Unlock Efficiency: Top Hollow Glass Production Lines for Your Company

1. Introduction

1.1 The Significance of Hollow Glass Production Lines in Manufacturing

If you’re running a glass business—whether you’re churning out windows for skyscrapers, windshields for cars, or that super thin glass for phone screens—you already know: Glass Production Lines are the beating heart of your shop. They aren’t just a bunch of machines; they decide how fast you can crank out products, how good those products are, and if you’re actually making enough money to keep the lights on. These days, if you wanna keep up with the competition, getting a solid Glass Production Lines isn’t something you can skip—it’s the only way to stay in the game.

1.2 How High-Efficiency Hollow Glass Production Lines Drive Business Success

Here’s the thing about a top-notch Glass Production Lines: it saves you cash without making you cut corners. I’ve seen factories slash the waste they throw away by nearly a quarter just by swapping to a better line—and their energy bills went down too! Plus, you can make way more stuff faster. No more panicking when a big order comes in because your old line can’t keep up. That speed and those savings? They go straight to your bottom line, and suddenly you’re standing out in a market that’s already packed.

2. Key Characteristics of Top-Notch Hollow Glass Production Lines

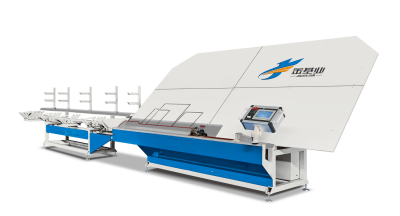

2.1 Advanced Automation Technology

The best Hollow Glass Production Lines these days aren’t just “automated”—they’re smart, y’know? Think AI that mixes up the raw materials perfectly every single time (no more batches that are off because someone messed up the measurements) and robots that handle the forming part 24/7. I popped into a glass plant last year, and they’d added automated defect checks to their line. Before that, workers had to spot flaws with their eyes—and let’s be real, they’d miss a few here and there. Now? The line catches issues right away, so almost every piece that comes out is perfect. That’s the kind of difference good automation makes for Glass Production Lines.

2.2 High-Precision Manufacturing Capabilities

If you’re making something like that ultra-thin glass for smartphones, precision isn’t a nice-to-have—it’s everything. Top Glass Production Lines can hit measurements down to a tiny fraction of a millimeter, which is why they’re the only ones that work for those specialized jobs. And here’s where a good Glass Production Lines manufacturer comes in: they’ll tweak the equipment to fit exactly what you need. I know a small company that makes custom glass for medical devices—their manufacturer calibrated the line to their unique specs, and now they never have to toss a batch because it’s not precise enough. Total game-changer for them.

2.3 Energy-Saving Features

Let’s talk sustainability—’cause it’s not just a trend, it’s a way to save money too! Modern Hollow Glass Production Lines use things like heat recovery systems. You know, they capture the heat from the melting process and reuse it instead of letting it go to waste. One client of mine told me this cut their energy bills by 25%—that’s thousands of dollars every month! And when you can say your production is eco-friendly? That’s a huge win for your brand, especially with customers who care about doing business with sustainable companies.

3. The Role of a Reliable Glass Production Lines manufacturer

3.1 Providing Customized Solutions

You don’t want a one-size-fits-all Hollow Glass Production Lines—your business isn’t like everyone else’s, after all! A trusted Glass Production Lines manufacturer will come to your facility, ask all the right questions (How much do you usually make? What kind of glass? Do you have limited space?), and build something that fits like a glove. For example, there’s a small glassware shop I worked with—they make mugs one week, vases the next, and they needed a compact line that could switch between the two easily. Their manufacturer designed exactly that—no wasted space, no extra features they’d never use. Perfect for their setup.

3.2 Offering Comprehensive After-Sales Support

Let me tell you a horror story: A factory’s Hollow Glass Production Lines broke down on a Monday morning, and their manufacturer took three whole days to send a technician. They lost $50,000 in orders because of it—yikes! You don’t wanna be that factory. A top Glass Production Lines manufacturer offers fast support—same-day repairs if they can swing it—and they’ll train your team to handle small issues on their own. There’s one manufacturer I always recommend; they even send monthly check-ins to make sure the line is running smoothly. That’s the kind of support that keeps your business from grinding to a halt.

3.3 Ensuring Quality and Durability of Equipment

A Glass Production Lines is a big investme

4. Benefits of Investing in High-Efficiency Glass Production Linesnt—you want it to last 10 years or more, right? The best manufacturers use tough materials, like heat-resistant steel, and they test the line like crazy before delivering it. I’ve seen lines that have been running for 15 years because the manufacturer didn’t cut corners on quality. On the flip side, a cheap line might break down every few months. You’ll end up spending more on repairs than you saved by buying the cheaper one. Trust me, it’s worth paying a little extra for something that’s gonna last.

4.1 Cost-Reduction in the Long Run

I get it—buying a high-efficiency Hollow Glass Production Lines feels like a big chunk of change upfront. But let’s do quick math: If a line saves you \(2,000 a month on energy and waste, and you paid \)50,000 for it, you’ll get that money back in just over two years. After that? It’s all pure savings. I had a client who was super hesitant to upgrade—they kept saying, “It’s too expensive!” But now they tell me it’s the best financial call they ever made for their glass business. Total no-brainer in the long run.

4.2 Improved Product Quality and Consistency

Nothing kills customer trust faster than inconsistent products. One week your glass is thick and clear, the next it’s thin and has bubbles—people will stop buying from you, plain and simple. A good Glass Production Lines fixes that. It heats the glass evenly, shapes it precisely, and checks for flaws every step of the way. For pharmaceutical companies, this is non-negotiable—their glass vials have to be perfect. With a reliable line, they never have to stress about a bad batch ruining their reputation. That peace of mind is priceless.

4.3 Enhanced Production Capacity

When the housing market booms, construction companies need tons of window glass—and they need it fast. I worked with a glass manufacturer that upgraded their Glass Production Lines, and suddenly they went from making 1,000 window panes a day to 1,500. They didn’t have to hire more workers or move to a bigger building—they just used their new line to its full potential. That’s how efficiency helps you grow without stretching your business too thin. It’s like getting more oomph out of what you already have.

5. How to Choose the Right Hollow Glass Production Lines

5.1 Assessing Your Production Requirements

Before you even talk to a manufacturer, ask yourself: What do I actually need? If you make solar panel glass, you need a line that can handle super high temperatures. If you make decorative glass, you need one with precision cutting tools. I once had a client who bought this huge, high-capacity line—but they only made small batches of custom glass. They wasted so much money on features they never used! Figure out your needs first, then find a line that matches. No need to overspend on stuff you don’t want.

5.2 Researching Reputable Hollow Glass Production Lines manufacturer

Don’t just pick the first manufacturer you find online—do your homework! Talk to other business owners in your industry—ask who they use and if they’re happy with them. Check case studies: Has the manufacturer worked with companies like yours? Do they have certifications for quality? I always tell clients to steer clear of “generalist” manufacturers—find one that specializes in Glass Production Lines for your niche. For example, if you make automotive glass, a manufacturer that only does construction glass might not get your specific needs. You want someone who knows your world.

5.3 Considering the Total Cost of Ownership

A cheap Hollow Glass Production Lines might seem like a good deal at first, but it’ll cost you more in the long run. Let’s break it down: Line A costs \(40,000, but it uses \)1,500 a month in energy and needs \(500 a month in repairs. Line B costs \)60,000, but it only uses \(800 a month in energy and \)100 a month in repairs. After five years, Line A has cost you \(130,000, while Line B is only \)108,000. See the difference? A good Glass Production Lines manufacturer will help you calculate these numbers upfront so you don’t get stuck with a costly mistake. No one likes buyer’s remorse!

6. Conclusion

At the end of the day, your Hollow Glass Production Lines is what makes or breaks your glass business. It’s not just equipment—it’s an investment in making things faster, better, and more profitably. And to get the most out of that investment, you need a trusted Glass Production Lines manufacturer—someone who builds a line for your needs, has your back after the sale, and makes something that’s gonna last. If you take the time to pick the right line and the right manufacturer, you’ll set your business up for success for years to come. Trust me, it’s worth the effort.