Butyl Extruder: The Essential Machine for High-Quality Insulating Glass Production

In the world of insulating glass manufacturing, precision and efficiency define the quality of the final product. Among all the essential equipment, the butyl extruder stands out as a crucial machine for ensuring airtight sealing, energy efficiency, and long-lasting durability of insulating glass units (IGUs).

What Is a Butyl Extruder?

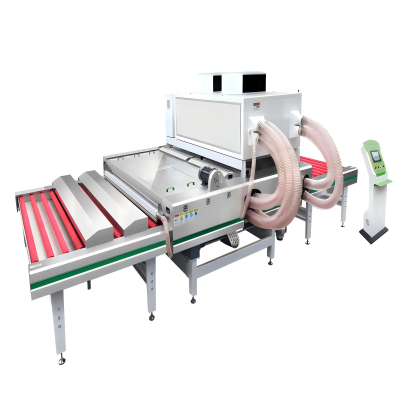

A butyl extruder is a specialized machine used to apply a uniform layer of butyl sealant onto the aluminium spacer frame during the production of insulating glass. The butyl layer acts as the first line of defense against moisture and gas leakage, ensuring excellent insulation performance.

This process may look simple, but it directly affects the thermal performance, lifespan, and appearance of every IGU. A high-quality butyl extruder guarantees perfect adhesion and smooth application, which is vital for modern energy-efficient windows.

How Does a Butyl Extruder Work?

The machine heats butyl rubber to a precise temperature, then extrudes it evenly through nozzles onto both sides of the aluminium spacer. The spacer then moves along the conveyor and is ready for desiccant filling and assembly with glass sheets.

Key components of a butyl extruder include:

Heating system: Maintains optimal temperature for consistent extrusion.

Pressure control: Ensures uniform butyl thickness on both sides.

PLC control system: Provides easy operation and accurate settings.

Dual-nozzle design: Allows simultaneous coating on both spacer sides for higher efficiency.

Advantages of Using a Butyl Extruder

Investing in a high-performance butyl extruder brings multiple benefits to glass processors:

✅ 1. Perfect Seal Quality

Uniform and stable butyl coating ensures airtight sealing, preventing moisture infiltration and argon gas leakage.

⚙️ 2. Enhanced Production Efficiency

Fully automatic systems with PLC controls reduce manual labor and speed up production without compromising precision.

🌡️ 3. Energy Efficiency

By maintaining consistent heating and pressure, the machine minimizes waste of materials and power.

🧩 4. Easy Maintenance

Modern butyl extruders feature modular designs and automatic cleaning systems, reducing downtime and service costs.

🪟 5. Long-Term Durability of IGUs

A precisely applied butyl layer ensures better insulation performance and longer life span of double and triple glazing units.

Where the Butyl Extruder Fits in the IGU Production Line

In an insulating glass production line, the butyl extruder is used after the aluminium spacer bending machine and before the desiccant filling and assembly process.

Here’s the typical workflow:

Aluminium Spacer Bending Machine – forms the spacer frame.

Butyl Extruder – applies the butyl sealant evenly.

Desiccant Filling Machine – fills the spacer with desiccant beads.

Glass Washing & Assembling – prepares the glass sheets for assembly.

Each machine plays a vital role, but the butyl extruder ensures the sealing integrity that keeps the IGU stable and weather-resistant.

Choosing the Right Butyl Extruder

When selecting a butyl extruder, consider the following features:

High precision temperature control system

Automatic pressure regulation

User-friendly PLC touch screen

Fast heating and stable output

Durable pump and nozzle materials

Compatibility with different spacer sizes

A reliable supplier will also provide training, maintenance support, and spare parts, ensuring long-term operation.

Why Modern Glass Factories Choose Advanced Butyl Extruders

In today’s market, energy efficiency and precision define competitiveness. Modern butyl extruders are not only about speed — they’re about consistency, reliability, and sustainability.

By adopting advanced butyl extrusion technology, glass manufacturers can:

Reduce waste and manual errors

Achieve perfect adhesion and uniform coating

Meet high-performance energy-saving window standards

Simply put, the butyl extruder is the heart of insulating glass sealing technology.

Conclusion

The butyl extruder is more than just a sealant applicator — it’s a key investment for any insulating glass manufacturer aiming for precision, quality, and long-term efficiency.

Whether you are upgrading your production line or starting a new one, choosing the right butyl extruder will help you deliver airtight, energy-efficient, and durable IGUs — keeping your business ahead in the competitive glass industry.