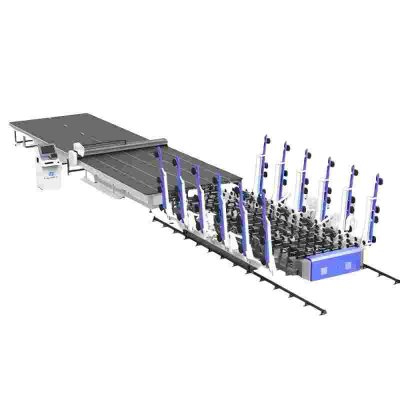

Insulating Glass Production Line

1. What is an Insulating Glass Production Line?

An insulating glass production line is an automated or semi-automated system designed to manufacture insulating glass units (IGUs). IGUs consist of two or more glass panes separated by spacers and sealed around the edges to create a dry gas-filled cavity, offering superior thermal insulation, soundproofing, and anti-condensation properties. These lines integrate key processes such as glass cleaning, drying, spacer application, sealing, and curing, ensuring high efficiency and consistent quality.

2. Working Principle

Cleaning & Drying: High-pressure sprays and brushes remove contaminants from glass surfaces, followed by hot-air drying to eliminate moisture.

Spacer Installation: Aluminum or stainless-steel spacers (containing desiccants) are applied along the glass edges to form the gas cavity framework.

Glass Assembly: A second glass pane is precisely aligned and pressed onto the spacer to create the preliminary IGU structure.

Sealing: Butyl sealant or polysulfide is applied to bond panes and prevent gas leakage, followed by outer-layer polyurethane or silicone sealant for structural integrity.

3. Advantages of Fully Automatic Lines

High Efficiency: Automated processes enable continuous production at speeds of 1–2 units per minute, with yield rates exceeding 95%.

Precision: Robotic arms and vision systems ensure alignment accuracy within 0.5mm, enhancing seal durability.

Energy Saving: Intelligent temperature control and waste recycling reduce energy consumption, aligning with sustainability goals.

Reduction: Cuts manpower needs by over 70%, ideal for large-scale manufacturing.

4. How to Choose the Right Line?

Production Capacit: Match line speed and configuration to annual output targets (e.g., 100,000–500,000 m²).

Functionality: Prioritize features like Low-E glass coating protection and automatic sealant application.

Brand & Support: Select reputable manufacturers (e.g., German, Italian, or leading Chinese brands) with reliable after-sales service.

Flexibility: Ensure adaptability to varying glass thicknesses (4–19mm) and sizes (up to 3000×6000mm).

Investing in the right insulating glass production line balances performance, cost, and scalability for long-term success.