How a Full Automatic Butyl Extruder Improves Efficiency in Insulating Glass Production

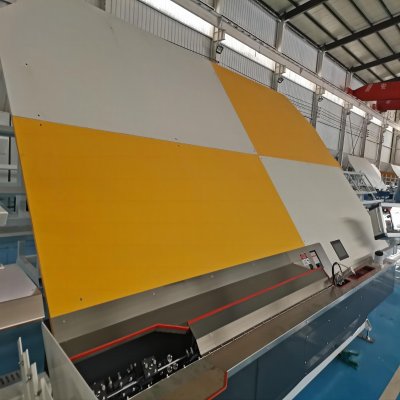

In insulating glass manufacturing, primary sealing is often underestimated, yet it directly affects long-term performance, moisture resistance, and production stability. As insulating glass factories expand output and face rising labor costs, many are replacing traditional equipment with an Automatic Butyl Extruder Machine to improve efficiency and consistency.

A Full Automatic Butyl Extruder is not just an automation upgrade. It is a practical solution for manufacturers who want stable quality, lower waste, and smoother daily production.

Understanding the Role of an Automatic Butyl Extruder Machine

An Automatic Butyl Extruder Machine applies hot-melt butyl sealant onto aluminum spacer bars before secondary sealing. Unlike manual or semi-automatic machines, it controls temperature, pressure, and coating width automatically throughout the entire process.

In real production environments, manual coating often leads to uneven thickness or inconsistent adhesion. A Full Automatic Butyl Extruder avoids these problems by maintaining stable parameters, even during long working hours or high-volume production.

Why a Full Automatic Butyl Extruder Increases Output

Production efficiency is not only about speed. It is also about reducing interruptions and rework. A Full Automatic Butyl Extruder allows continuous coating without frequent adjustments or shutdowns.

From factory experience, manufacturers usually see:

Faster spacer bar processing

Less dependence on skilled manual operators

Fewer sealing defects during secondary sealing

By installing an Automatic Butyl Extruder Machine, insulating glass producers can increase output while keeping quality under control.

Stable Sealing Quality with an Automatic Butyl Coating Machine

Primary sealing quality depends heavily on coating accuracy. An Automatic Butyl Coating Machine ensures that butyl sealant is applied evenly on both sides of the spacer bar.

This results in:

Consistent coating width

Clean sealing edges

Reliable moisture barrier performance

Compared with manual coating, an Automatic Butyl Coating Machine significantly reduces common issues such as sealant overflow or insufficient sealing, which often cause IGU failure over time.

Reducing Material Waste and Operating Costs

Butyl sealant consumption is a major cost factor in insulating glass production. A Full Automatic Butyl Extruder applies sealant precisely, avoiding unnecessary waste.

In long-term operation, an Automatic Butyl Extruder Machine helps manufacturers:

Lower sealant usage

Reduce rejected units

Decrease maintenance caused by poor sealing

These improvements lead to more predictable production costs and better profit control.

Easy Integration into Existing Production Lines

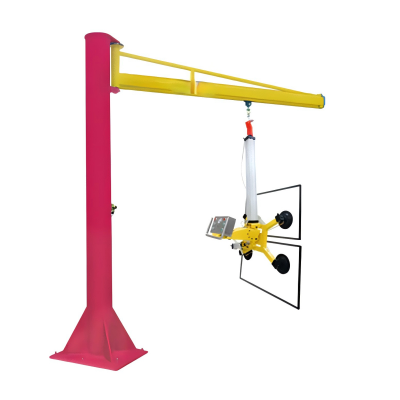

Most modern factories require equipment that works smoothly with existing systems. A Full Automatic Butyl Extruder is designed to integrate easily with aluminum spacer bending machines and insulating glass assembly lines.

Whether used independently or as part of a complete line, an Automatic Butyl Extruder Machine supports flexible layouts and future automation expansion.

Why More Insulating Glass Manufacturers Are Upgrading

As insulating glass standards become stricter, manufacturers are under pressure to deliver consistent quality at higher volumes. An Automatic Butyl Coating Machine helps meet these demands without increasing labor intensity.

For many factories, choosing a Full Automatic Butyl Extruder is a practical step toward stable production, better quality control, and long-term competitiveness.

Conclusion

A Full Automatic Butyl Extruder plays a key role in improving efficiency and sealing quality in insulating glass production. With precise control and stable performance, an Automatic Butyl Extruder Machine helps manufacturers reduce waste, improve consistency, and maintain reliable primary sealing. Combined with an Automatic Butyl Coating Machine, it becomes an essential part of a modern insulating glass production line.